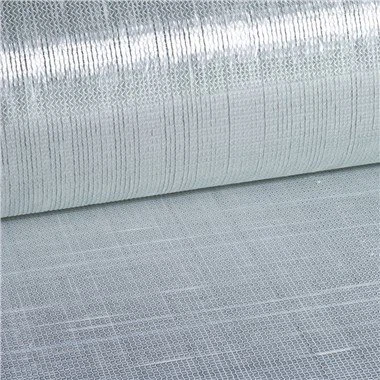

The state of different quality PTFE high temperature cloth at high temperature

Mar 11, 2018

After the PTFE n high-temperature cloth PTFE tape is baked at high temperature, there will be residual glue, glue overflow and other phenomena. It will be found that there are tiny residues through hand feel or close observation, and this tiny residue has a great impact on production. This phenomenon may be that the high temperature resistance data of the tape does not meet the production requirements. The high temperature resistance required is usually 210-260 degrees, so it should be confirmed before production whether it meets the production requirements. In response to the phenomenon of residual glue, the quality of PTFE high-temperature cloth should be controlled first. Before being put into production, a preliminary high-temperature screening test of ozone should be carried out to meet the company's requirements before use.

Since PTFE high-temperature cloth belongs to a high-tech process, the raw materials contain chemical components in the production process, and many factors such as the environment used by each customer, coating equipment, technical requirements, production processes and personnel operations, in the production process. Abnormal phenomena will inevitably occur. If the temperature of the production line is too high, which is not within the technical requirements, residual glue will also appear. You should check whether the temperature sensor is normal. The PTFE high-temperature tape product itself will also have quality problems. If the sensitive baking data is not strictly pressed during the production process, Insufficient curing time or too fast coating speed will result in the inability of glue, primer and substrate to combine.

When the PTFE high-temperature cloth passes through the coating machine, it is coated with the rubber roller. Generally, the semi-finished product needs to be left for 2-3 days before it can be re-rolled and cut for use. This is mainly to fully combine the glue and the substrate, and the glue is fully cured in the natural state. If it is not fully cured until it is re-rolled and cut, residual glue will appear. There is glue residue in the production process of PTFE high temperature cloth, and abnormal workpieces should be removed and stored separately. In order to avoid this phenomenon, the detection of online products should be strengthened. After a period of time or a certain number of bad statistics, the percentage of residual glue rate should be analyzed according to the actual situation to find out the root cause of the problem, so that the production process will not fail.