Comparative Analysis Of Aerogel Insulation Felt And Traditional Insulation Materials

Mar 29, 2022

Aerogel, also known as xerogel. It is a highly dispersed solid material with a nanoporous network structure composed of colloidal particles or polymer molecules and filled with gaseous dispersion medium in the gaps, and the appearance is solid. Aerogel was first prepared by American scientist Kistler in 1931 by hydrolyzing water glass. Subsequently, with the deepening of aerogel research and the gradual improvement of supercritical drying technology, the solid particles that constitute the aerogel tend to be more refined, and the micropore distribution tends to be more uniform, so that the density of the material is lower and the porosity of the material is lower. higher. Aerogel is the lightest known solid in the world, with a density of only 0.16 mg per cubic centimeter, and its appearance is light blue, also known as: "frozen smoke" or "blue smoke".

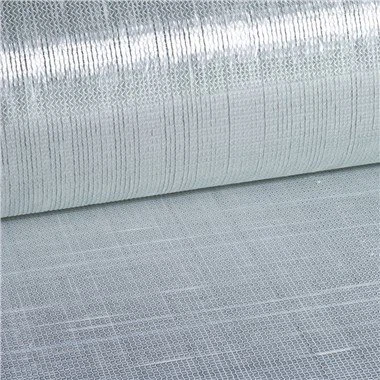

A common aerogel material on the market is nano aerogel insulation felt, a flexible insulation material that combines aerogel into a flexible substrate through a special process. The traditional thermal insulation materials mainly include aluminum silicate, glass wool, rock wool, rubber and plastic, polyurethane, etc. In the past few decades, traditional thermal insulation materials have played a huge role in their respective fields, providing thermal insulation for the industry. , reduce energy consumption for urban buildings. With the development of the times and the advancement of science and technology, traditional thermal insulation materials are increasingly unable to meet people's requirements for high efficiency and energy saving. So are there new insulation materials to replace these traditional insulation materials? That is nano-aerogel insulation felt. Compared with traditional insulation materials, aerogel insulation felt has the following advantages.

1. Low thermal conductivity (good thermal insulation effect)

The index to measure the thermal insulation effect of thermal insulation materials is thermal conductivity. The thermal conductivity of aerogel insulation felt is 0.020W (mK), while the thermal conductivity of traditional thermal insulation materials is 0.028W (mK)-0.045W (mK). Low, it is possible to achieve the same thermal insulation effect with a thinner thermal insulation thickness. In the following illustration, the use of aerogel insulation felt can effectively reduce the thickness of the wrapping layer and reduce heat loss.

2. Good waterproof effect

The hydrophobic rate of aerogel insulation material is as high as 99%, which can effectively reduce the generation of condensation during use, and better protect the pipeline layer from corrosion and damage. However, traditional thermal insulation materials are very easy to absorb water during use, resulting in an increase in thermal conductivity, a decrease in thermal insulation effect, and corrosion of the pipeline layer.

3. The product has a wide temperature range

Aerogel insulation blankets can be used in a wide range of temperatures, ranging from -200°C low temperature to 650°C high temperature. In traditional thermal insulation materials, ordinary rubber and plastics can reach the lowest temperature of -40℃, while the high temperature can only reach 120℃; in the high temperature field, aluminum silicate can withstand high temperature up to 800℃, but it is not resistant to low temperature. In most other thermal insulation materials, the highest temperature is only about 100 ℃.

4. National Class A non-combustible fire rating

Aerogel insulation felt is an inorganic material and has reached the national A-level fire rating, while among traditional insulation materials, rubber, plastic and polyurethane are organic materials that are prone to fire.

5. Long service life

The service life of the aerogel insulation felt can reach 20 years, and there is no need to replace any material during the 20 years, which effectively reduces the cost of replacing the insulation material and the cost of construction and operation.